OptiFlowi nterface for TripleTOF 6600 system

Switch from nanoflow LC to microflow LC in minutes

Chiu Cheong Aw1, Christie Hunter2

1SCIEX, Singapore, 2SCIEX, USA

Introduction

In a busy Omics research lab or MS core facility, there are often a diverse range of projects to run during a single week. Therefore, the ability to easily switch between LC-MS workflows can help improve productivity. For routine projects where ample material is available, it is often useful to use microflow LC to analyze samples with accelerated throughput. This can free up time to spend on more complex, higher sensitivity projects that require nanoflow LC.

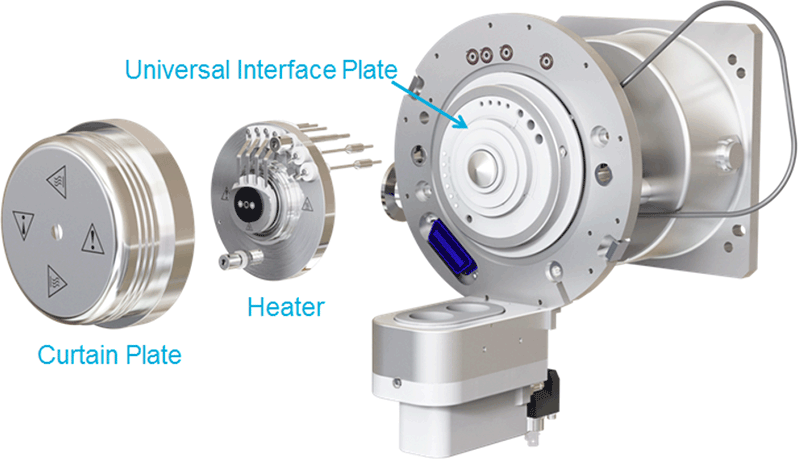

OptiFlow™ Interface together with the nanoLC™ 425 System enables switching between LC-MS workflows in minutes, enhancing overall system productivity. After removing the nanoflow source (either the OptiFlow® Source in nano mode or the NanoSpray® Source), the nanoflow curtain plate and heater can be quickly removed from the universal interface plate (Figure 1). Then the high flow curtain plate and a higher flow rate source (either the Turbo V™ Source or the OptiFlow Source in micro mode) can be mounted. Since the interface plate stays in place, there is no vacuum break required, allowing the switch to higher flow applications to be performed in minutes.

Figure 1. OptiFlow Interface for rapid switching between high flow and low flow sources. Easily switch between all front end operational modes in minutes, without having to break vacuum. For low flow applications, remove the high flow Curtain Plate, then install the nanoflow heater onto the Universal Interface Plate, and finally install the nanoflow Curtain Plate.

Key features for the OptiFlow Interface

- With this universal interface plate, users can switch between ionization sources in minutes, without breaking the MS vacuum

- No tools required

- Use the Turbo V™ Source for high flow applications

- Use the OptiFlow Source, NanoSpray® Source or Digital PicoView source for low flow applications

- SelexION® Technology for performing differential mobility separation experiments

- Using the nanoLC 425 System, user effectively has two LC systems in one

- High performance dual gradient system with the flexibility and reliability to support a broad range of Omics workflows1

- Set up system with one channel in nanoflow mode and the other channel in Microflow mode

- Switch LC between flow regimes in minutes2

- Coupled with the TripleTOF 6600 or 6600+ System for global discovery and targeted quantitative applications

- Couples with OptiFlow Source on TripleTOF 6600+ System4

Equivalent or better performance on OptiFlow Interface vs nanoDCI interface

To confirm the performance of the nanoflow heater and curtain plate for the OptiFlow Interface were equivalent or better than the previous nanoDCI heater and curtain plate, multiple OptiFlow Interfaces were compared to the nanoDCI on a single TripleTOF® 6600 System using the standard tests described in the SWATH® Acquisition Performance Kit3.

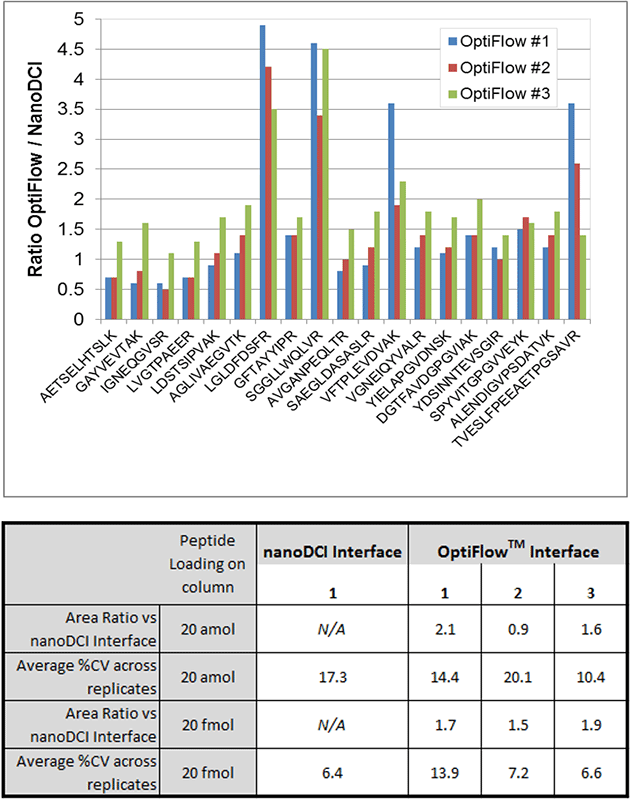

First, the PepCalMix was run by nanoflow LC-MS at two different concentrations on the multiple interfaces for comparison. The peptide areas from the OptiFlow Interfaces were compared to the signal obtained from the nanoDCI interface (Figure 2) and the ratios were found to be equivalent or greater than 1, indicating equivalence or better performance. This was observed at both the higher (20 fmol) and lower (20 amol) loadings on column. Three replicate injections were performed for each tests and similar %CV were also observed. When the ratios were compared for the individual peptides (Figure 2, top), very similar performance patterns were observed across the peptide properties and retention times.

Figure 2. Peptide performance testing shows equivalent or better performance using the OptiFlow Interface. Multiple OptiFlow Interfaces were installed on a single TripleTOF 6600 System, to measure LC-MS performance for PepCalMix relative to the original nano DCI interface (Top). Using two different sample loading amounts, very similar performance was observed overall (average ratio vs nanoDCI in table) with an average ratio of 1.6.

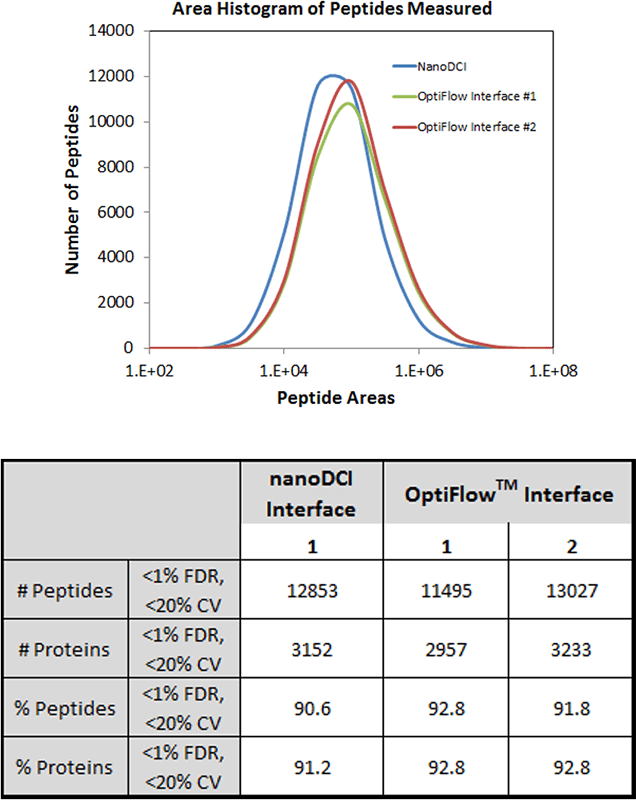

SWATH Acquisition tests were also performed using a complex cell lysate digest, this time comparing two OptiFlow Interfaces to the nanoDCI interface on a single TripleTOF 6600 System. Similar peptide area distributions were observed across the replicates of the 3 tests (Figure 3, top), measuring over 10000 peptides. This similarity in peptide areas resulted in similar numbers of peptides and proteins quantified at a <1%FDR and <20% CV across the three tests (Figure 3, table). Also the cumulative CV curves were compared and in all 3 tests, ~90% of the peptide/protein data had reproducibility of better than 20%CV across the replicates performed, confirming both the performance and the robustness of the SWATH Acquisition workflow with the OptiFlow Interface.

Figure 3. SWATH Acquisition performance testing across multiple OptiFlow Interfaces. Using the SWATH Performance kit, the quantitative performance of two OptiFlow Interfaces was compared to the original nanoDCI interface on a single TripleTOF 6600 System. Similar peptide area distributions were measured on the 3 interfaces (top) resulting in very similar # of proteins and peptides were quantified in all three tests (Table).

Conclusions

OptiFlow Interface together with the nanoLC 425 System enables switching between LC-MS workflows in minutes, enhancing system productivity for the busy research lab. Results here outline some of the validation work that was performed to confirm the performance of the OptiFlow Interface was equivalent or better than the original nanoDCI interface. For a simple peptide mixture or a complex digested cell lysate, similar peptide signal intensity was observed between the different interfaces when tested on the same TripleTOF 6600 System.

References

- Achieving very high reproducibility for quantitative proteomics with nanoflow LC-MS - NanoLC™ 400 Series System, SCIEX technical note RUO-MKT-02-5755-A.

- Easily switch from nanoflow to Microflow with OptiFlow™ Interface and nanoLC™ 425 System. SCIEX video.

- SWATH performance kit. SCIEX product page.

- Single source solution for low flow chromatography - OptiFlow™ Turbo V Source – always working in the sweet spot of sensitivity and robustness. SCIEX technical note RUO-MKT-02-9701-A.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge