Combining high data quality and high-throughput analysis

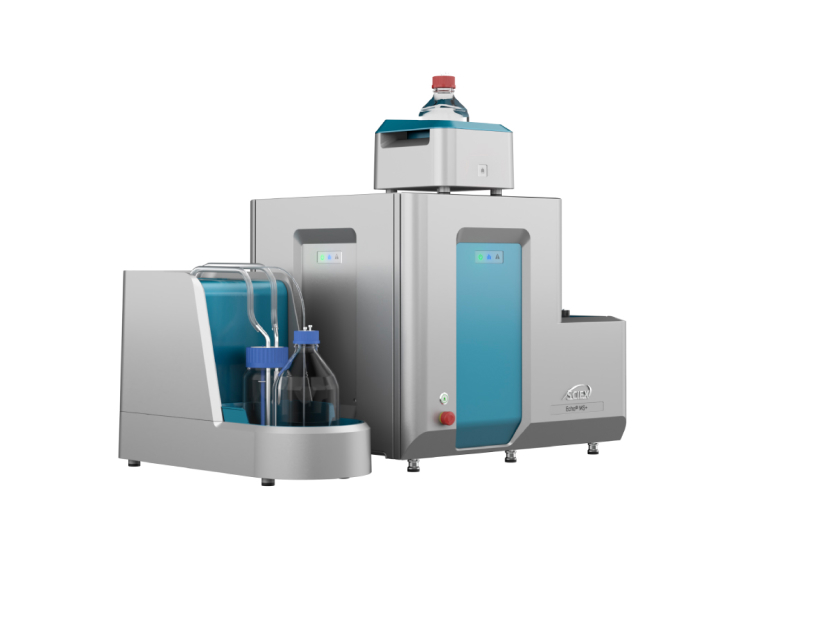

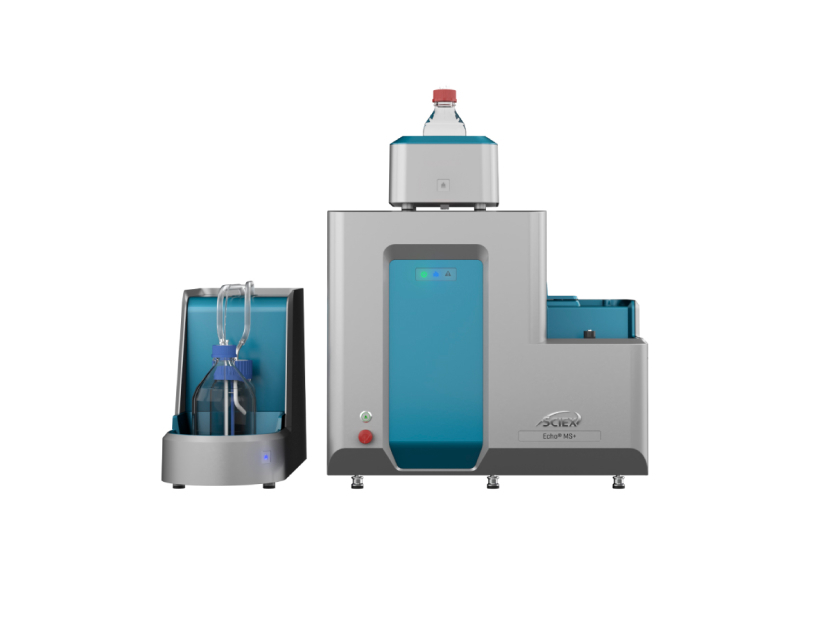

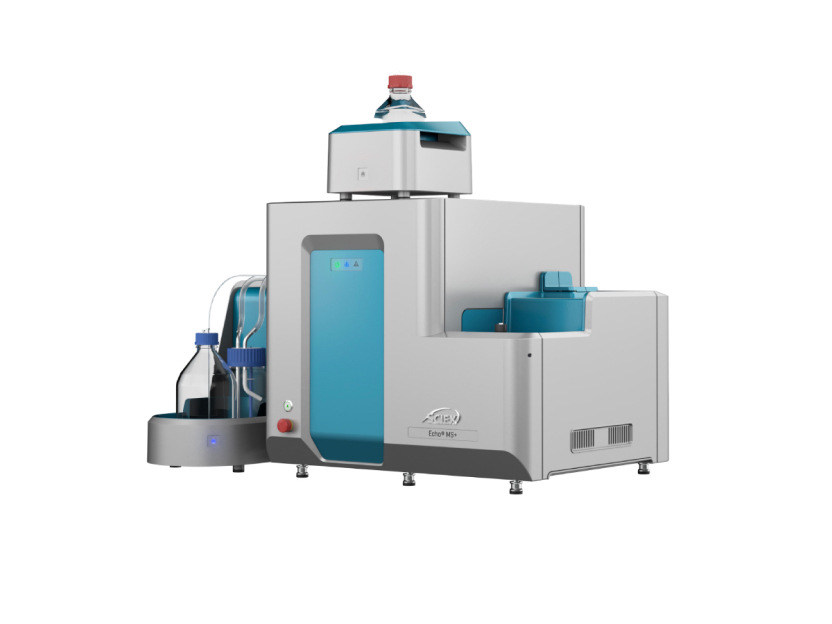

When the quantity of samples is your challenge, breakthrough with the Echo® MS+ system. The Echo® MS+ system gives you high-quality data, analytical flexibility and high sample throughput so you can make informed decisions, today. With sampling rates of up to 1 sample per second, results can be generated on the same day. The Echo® MS+ system is a complete solution that removes bottlenecks in high-throughput analytical workflows, from sample preparation to data reporting.

Benefits

High-quality data

The Echo® MS+ system is compatible with either the SCIEX Triple Quad 6500+ system or the ZenoTOF 7600 system for trusted mass spectrometry performance.

Contactless sampling

Sample ejection allows for rapid sampling and reduced carryover.

Designed for automation

The system is compatible with robotic automation systems—automating steps such as sample preparation, plate preparation, plate loading/unloading, and plate submission for analysis.

Longer operational robustness

The port wash allows for cleaning the electrode assembly between sample plates, increasing the number of ejections that generate high quality data before you need to manually replace consumables.

Method flexibility

The new features of SCIEX OS software allow: Enhanced solvent and additive options for analytical flexibility Data acquisition modes to enable robust quantitative and qualitative capability The ability to analyze samples directly from a DMSO matrix

Get more information

Redefining high-throughput mass spectrometry

Quality

Deliver high-quality data, minimize sample handling and eliminate carry over with contactless acoustic ejection sampling. Retain the precise, information-rich data needed to make informed decisions about your samples.

Precision

Achieve unparalleled standards of quantitation and qualification, at speed. The Echo® MS+ system provides consistency and precision in challenging matrices. Its high specificity enables confidence in results, and both decreases the need for re-runs and saves on reagent costs when compared to other technologies.

Speed

Conquer throughput barriers and decrease overall turnaround time with sampling speeds of up to 1 sample per second. Screen substrate and product simultaneously and reduce the number of analytical steps in your process.