Acoustic droplet ejection

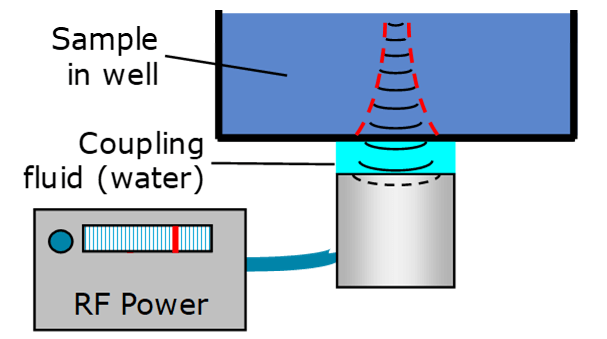

Acoustic Droplet Ejection platforms have been widely adopted in high-throughput screening labs and are used to rapidly, accurately and precisely transfer nanoliter volumes of liquids between plates. Acoustic energy is used to create, and then amplify, a standing wave in liquid in a sample well. As the amplitude of the standing wave increases, a point is reached when a single droplet is ejected from the wave at its central apex (Figure 2). This is a well characterized process that can be very tightly controlled, generating consistent volume droplets from liquid in a plate well on a microsecond time scale. The sample plate, a standard footprint 384- or 1536-well plate, is articulated over the fixed position acoustic module by a pair of XY stepper motors. The stepper motors rapidly move the plate from well to well, allowing each well to be sampled in turn. In the Echo MS System, the acoustic ejection module is used to very reproducibly generate sample droplets of approximately 2.5 nL, depending on the viscosity of the liquid, in an individual ejection pulse. Additionally, multiple ejection cycles can be sequentially run very quickly, from 200 to 500Hz depending on the sample liquid, so multiple droplets effectively merge together for a larger effective ejection volume.

Open port interface

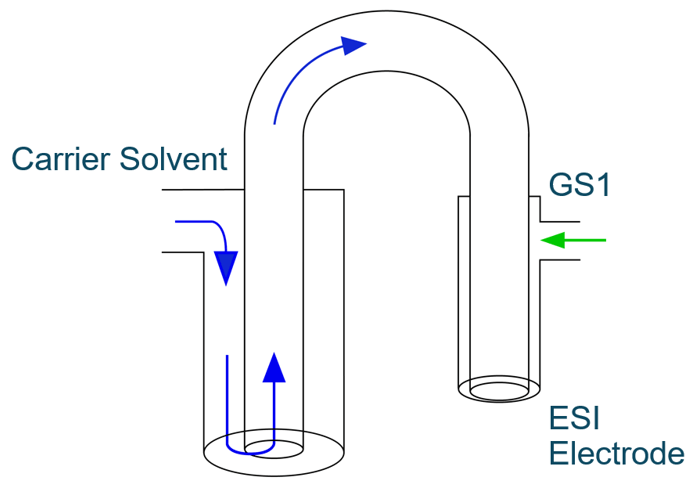

The second main component is the Open Port Interface (OPI), developed in collaboration with Oak Ridge National Laboratory, which provides a mechanism that allows the capture and transfer of the acoustically ejected droplet to the electrospray source of the mass spectrometer. The OPI is a pair of concentrically positioned tubes that are both open at one end (Figure 3). The outer tube has liquid (carrier solvent) delivered to it by a low pressure liquid pump. The inner tube is connected, via a transfer line, directly to the capillary of the ESI source. The nebulizer gas (GS1) provides an aspirating “pull” that draws the solvent delivered from the outer tube into the inner tube. The vortex that results when the carrier solvent makes the turn from the outer tube to the inner tube is where the droplet, created by acoustic ejection, enters the liquid flow and is then carried to the ESI source. One advantage of the small droplet size being introduced into the liquid stream is that the significant dilution can help to minimize matrix suppression effects.

On the Echo MS System, the OPI position is fixed above the acoustic module, so that the sample plate moves from well to well between these elements. The sample plate can move very quickly and is capable of allowing three wells to be sampled in one second.

Mass spectrometry

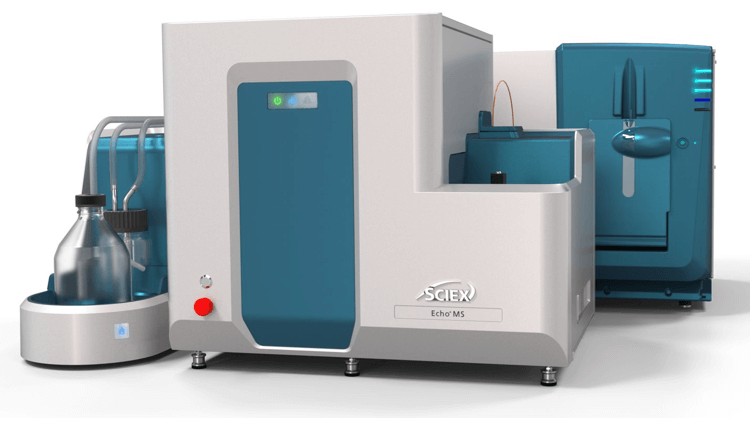

Finally, the liquid stream is vaporized and ionized compounds are specifically quantified using the SCIEX Triple Quad 6500+ System. Fitted with the OptiFlow Source and the specially developed transfer line from the OPI, this mass spectrometer provides industry-proven sensitivity and robustness, and is an ideal detector for the Echo MS System for high-throughput, quantitative work.

Software and automation

The Echo MS System can run as a stand-alone analyzer, operated through SCIEX OS Software. This provides an easy to implement platform for high-throughput quantification from individual plates. However, the system was purpose built to be incorporated into an existing high-throughput environment. The plate holder is positioned so that it is easily accessible to a robotic arm. The SCIEX OS Software has a well-documented instrument control API that allows the system to be controlled by third-party scheduling software. When analysis of a plate is complete, the system will generate a .csv file, containing automatically integrated peak areas, as well as sample names and well locations. This file can be automatically imported by a LIMS.

Quantitative data generation

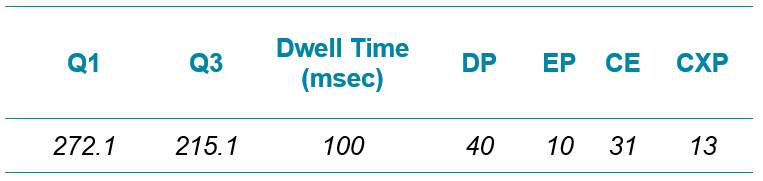

For an analytical system to be truly quantitative, it must be able to perform to certain accepted standards. It should be capable of quantifying across a usable linear dynamic range, it must be accurate and reproducible, and it should not be prone to significant carryover effects from sample to sample. In the case of a high-throughput system, these capabilities must be maintained at the required rapid timescale. To illustrate the Echo MS System capabilities, a series of experiments were run using dextromethorphan as a reference compound, diluted in 10% methanol in water (v/v). Methanol was used as a carrier solvent, and details of the MRM method conditions are listed in Table 1.

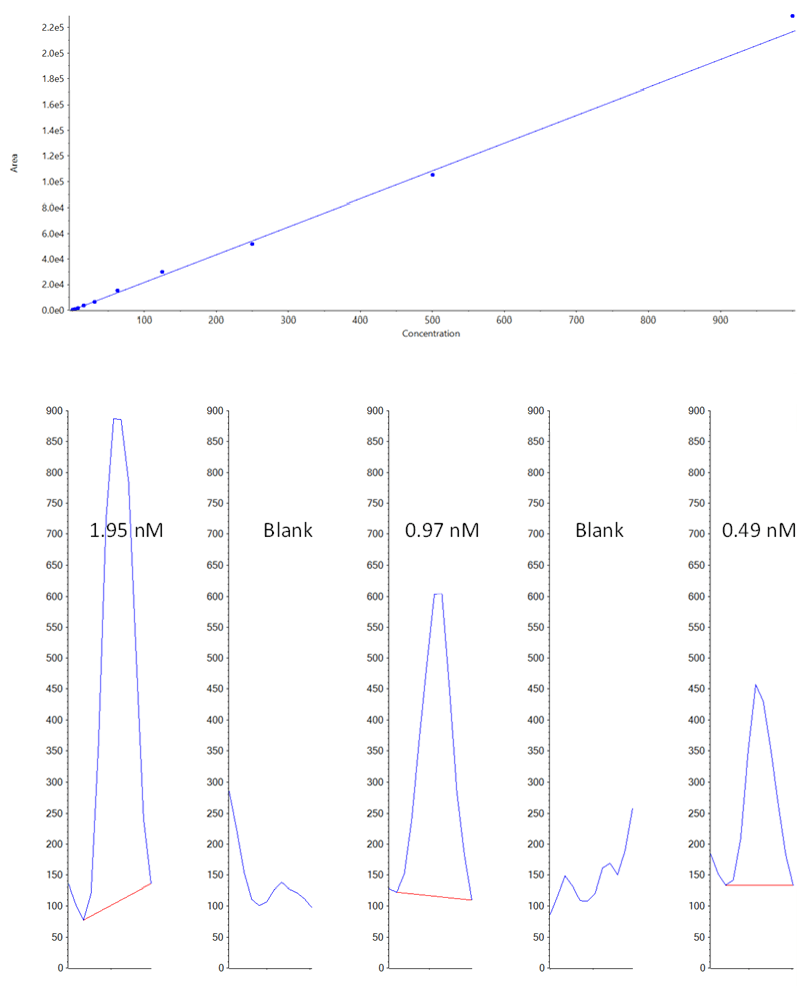

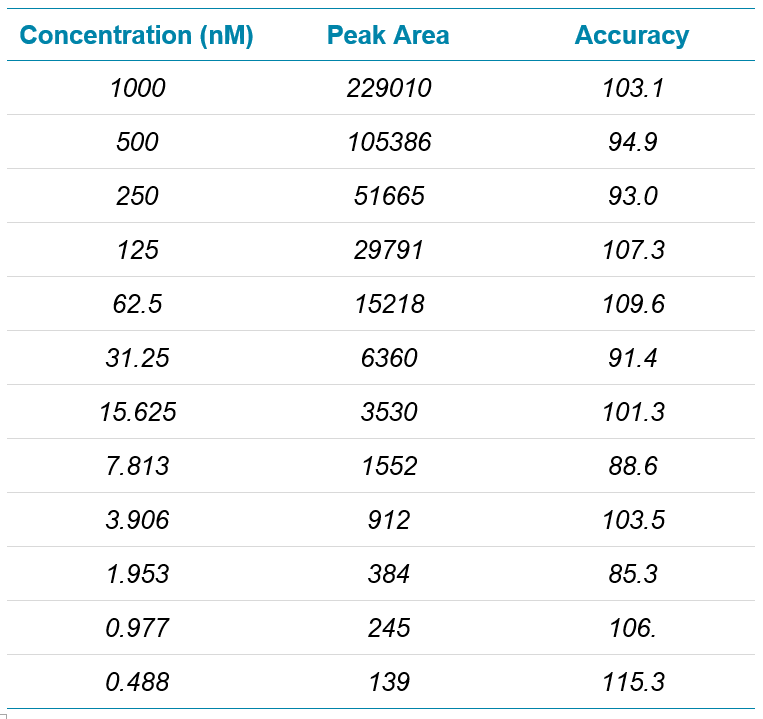

Linearity and carryover

Dextromethorphan was serially diluted, 1:1 in 10% methanol in water, from 1000 nM to 0.488 nM, and then a 50 µL sample aliquot was transferred to a 384-well plate (Beckman Life Sciences 384PP 2.0 Microplate). In addition to the working standards, 50 µL aliquots of pure diluent were also transferred to other wells in the plate. The calibration curve was run from highto low, with blanks being run in between each standard. This was done to assess both linearity and carryover susceptibility.

The system showed good linearity across the tested range (Figure 4, Table 2), although the low point (0.488 nM) might not have a high enough S/N to be considered a true LLOQ. Importantly, there was no observable carryover from even the highest concentration calibrant (data not shown).

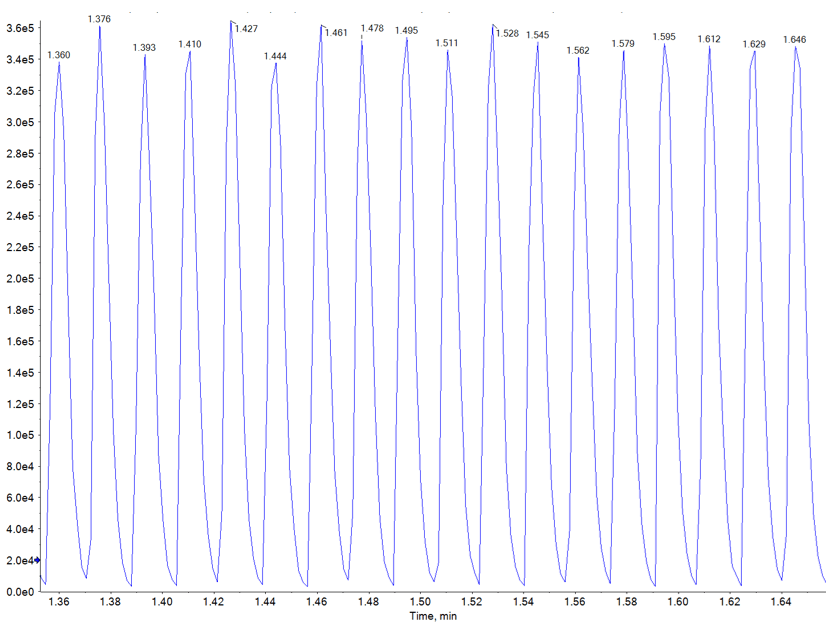

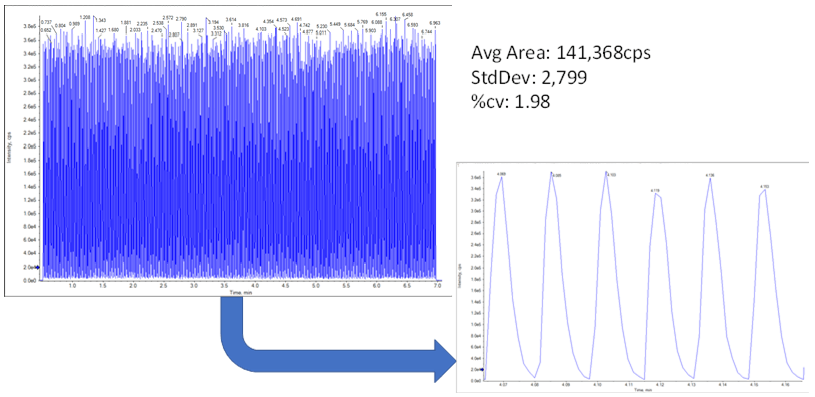

Speed of analysis and precision

To illustrate the native precision of the system while acquiring data at a rate of one sample per second, 20 mL of dextromethorphan solution was prepared at a concentration of 100 nM in 10% methanol in water, and 50 mL aliquots were transferred to all wells of a 384-well plate. Data for every sample well in the plate were acquired in just over six minutes (Figure 5, and detail in Figure 1). MRM peaks obtained from each well were integrated using SCIEX OS Software. Peak areas were highly reproducible, with 1.98 %CV across all 384 wells.

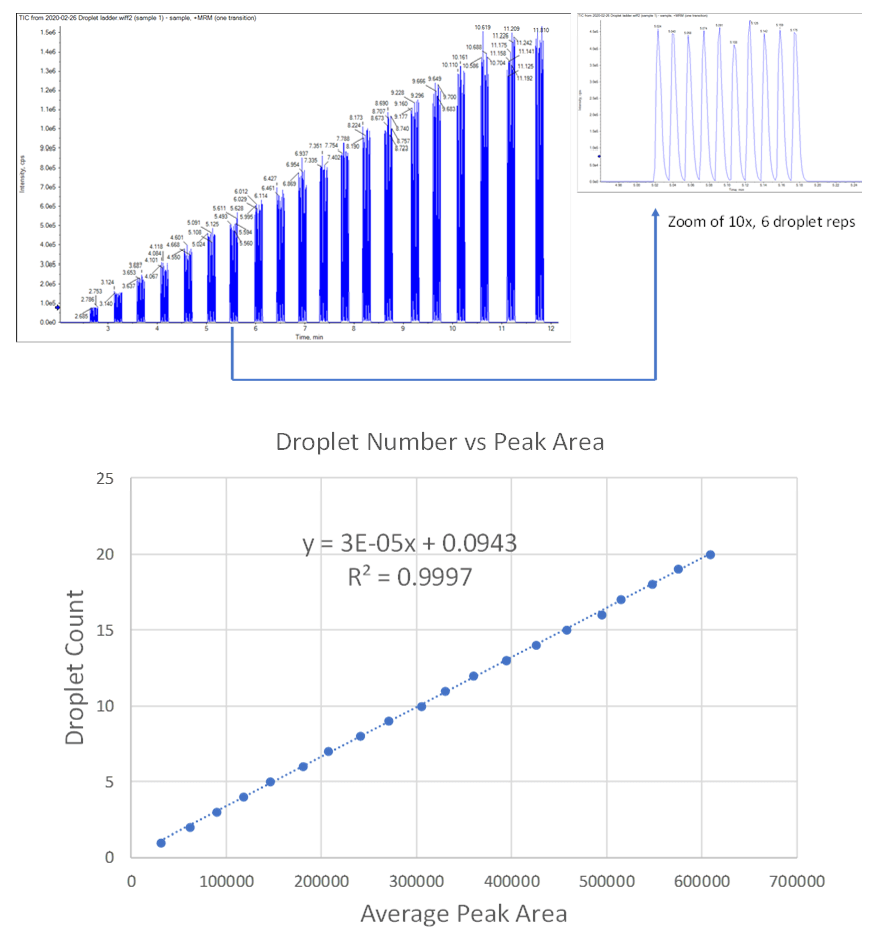

Quantitative droplet generation

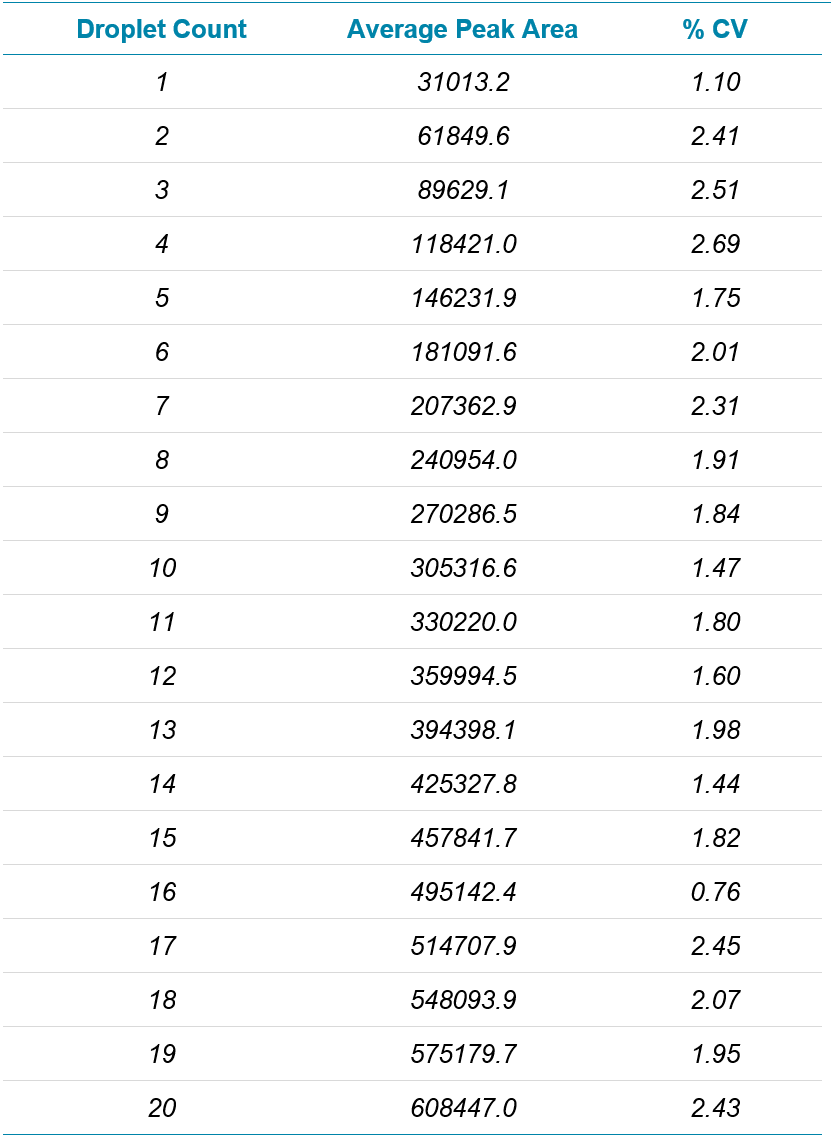

A useful aspect of the Echo MS System is the ability to specify, in the acoustic ejection method, the number of droplets ejected during analysis. The droplet size is based on a complex interplay of the frequency of the acoustic energy and the viscosity of the liquid in the sample well. It should be considered a fixed value for a given liquid. Because droplets can be created so quickly, on a microsecond scale, the ejection of multiple droplets in a group as a single sampling event can have the effect of increasing, in a very reproducible manner, the amount of sample transferred to the OPI and into the mass spectrometer. The linear range of droplet grouping can be matrix dependent, with sticky or viscous matrices (such as untreated plasma) having a narrower linear droplet range.

To demonstrate, a series of ejections were performed using dextromethorphan. The ejections ranged from one to twenty droplets, generating a “droplet ladder” (Figure 6, top). Table 3 lists the average areas with the %CV obtained for the 10 replicates across the droplet ladder. The plotted linearity is shown in Figure 6. All ejections for this experiment were done from a single sample well. The ability to quantitatively control the sample introduction volume, which is analogous to an injection volume in standard HPLC work, can be very helpful during method development.

Conclusions

The newly developed Acoustic Ejection Mass Spectrometry (AEMS) system —the SCIEX Echo MS System— has the potential to dramatically change the field of high-throughput analysis:

- Quantitative ESI MS/MS analysis speed is now much closer to that of a plate reader, while preserving the ease of method development, ability to monitor multiple analytes simultaneously, specificity and dynamic range of mass spectrometry

- Excellent reproducibility of ejection (with 1.98 %CV across all 384-well plate) has been demonstrated

- The system’s hardware and software were designed for inclusion in a high-throughput environment. The sample plate holder is positioned in such a way that standard robot arms can transfer plates to and from it easily. The open API allows scheduling software to control the system without the need for human intervention.

- Data processing and export can also be automated. After data for the plate are acquired, they are processed using a quantification method. A .csv file is automatically generated, with information including well number, peak area and sample name, which can be imported by a LIMS.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge